Brought to you by Martin Reddy from GreenIT

How does the reuse and refurbishment of technology products look like in practice? Project partner, GreenIT, an ICT (Information and Communication Technology) refurbishment and remanufacturing (reuse) company based in Ireland – in the North Atlantic Ocean – opened its doors to guide us through the process.

Finding suitable stock

The first part of any reuse company is sourcing suitable stock for processing. The two main markets for ICT Reuse equipment are the Consumer market (B2C) and the Business market (B2B). The B2C market is not a suitable source of material as the quality, consistency and specification can be of a lower grade in many cases – this combined with availability and the lack of correct handling make the B2C market more suitable for recycling rather than reuse.

This leaves the B2B market where the equipment is of a higher specification and build quality and is the best source of reuse equipment. Again, there are many sources within the B2B market for sourcing ICT but they breakdown into three primary areas:

- The first and the most labour intense source is directly from the business owner, as the assessment, security, and potential valuation of the equipment must be conducted by the reuse company.

- Second is the leasing company who are just looking for the best value return for their equipment at the end of its lease and first use.

- Third and the most prevalent is the broker who acts as the man in the middle for business owners and leasing companies and who simply wants to buy and sell as much ICT as possible, as quickly and profitable as feasible.

Selling the acquired stock

At the end of the sourcing journey, there are a variety of reuse companies eager to sell their acquired stock.

Reseller

The reseller is usually after the lowest cost equipment that needs truly little processing so it can be sold as quickly and cheaply as possible. The reseller typically does not add value to the supply of reused equipment and may sell the equipment as is or at best in grades depending on the condition of the equipment. The grades set are normally A, B or C can be vastly different depending on the reseller. The typical reseller can be found on sites like eBay etc. and the equipment although cheap can be of inferior quality, both cosmetically and functionally speaking.

Refurbisher

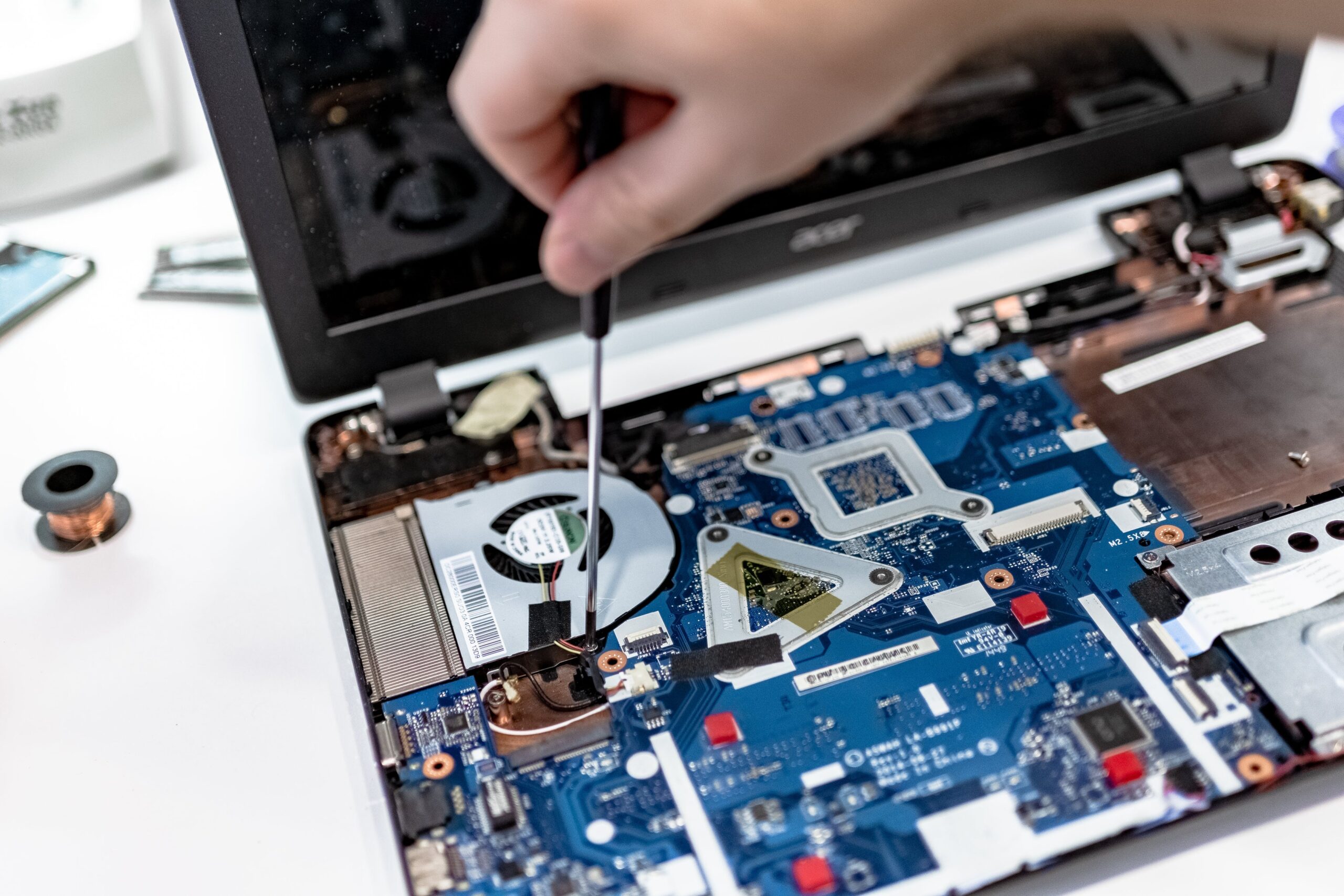

A typical refurbishment company adds value, quality, security, and legality to the equipment for reuse.

Value is added by upgrading the equipment and making it a Grade A standard by repairing, respraying, reprinting, and localising the equipment – this can include reprinting of keyboard to local languages, or respraying of covers to hide any blemishes.

The refurbisher will also upgrade the equipment where required, securely data wipe the old user’s data and add a new operating system licence. The typical refurbisher will have its own web presence and sell directly to the consumer with a comprehensive warranty. The growing market for quality refurbished ICT has increased the demand for an offering that is equal to new both in quality and after sales support.

Remanufacturer

Remanufacturing stands out from refurbishment as it places products on the market as new and with a warranty to match the Original Equipment Manufacturer (OEM).

Remanufacturing has a heavy load to carry with the intense processing and labour costs involved in producing a product that is undistinguishable from new in every way. The source of material has to be of high quality and quantity to begin with so a typical remanufacturer may have a smaller portfolio of equipment than a refurbisher as a way to reduce the cost involved.

GreenIT’s venture into remanufacturing means we source our equipment outside of Ireland to ensure a suitable quantity and quality, which is an added cost as everything must be shipped from mainland Europe or beyond.

Digital Product Passport

The development of a Digital Product Passport would support our efforts when looking to streamline our processing by making information readily available during the processing phase. To have the OEM specifications and potentially the parts for each component readily available would reduce processing times and costs.