Brought to you by Tian Daphne and Daniel Gregory from Circularise

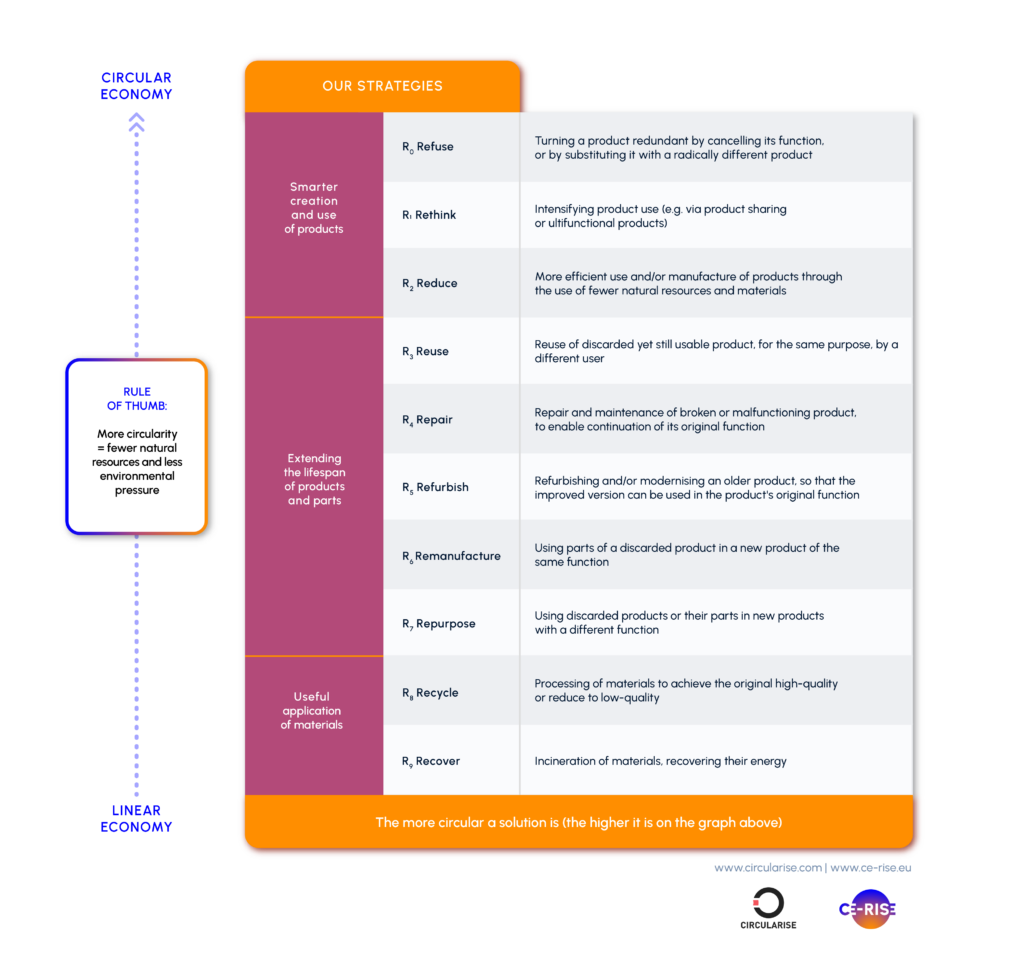

The circular economy provides a compelling framework for sustainable resource management and waste reduction. At the core of this approach are R-strategies, a collection of principles designed to optimise resource efficiency, minimise waste, and promote the recovery and reuse of materials. The more circular a solution is (the higher it is on the graph below), the more it means that the end-of-life has been considered from the product design stage.

The CE-RISE project is championing the widespread adoption of Digital Product Passports (DPPs) for product lifecycle management. DPPs serve as a digital ledger, providing detailed information that enhances the transparency and traceability of products throughout their lifecycle, instrumental in advancing the ten R-Strategies, focusing on three primary objectives for a circular economy.

The first objective revolves around creating smarter products that are used and manufactured efficiently. Information on how a product performs over its life cycle incentivises the designer to consider the entire life cycle of the product, leading to critical design decisions that can reduce or eliminate the use of materials or processes incompatible with the circular economy.

- R0 Refuse: Make a product obsolete by disregarding its functionality and offering alternative products that serve the same purpose.

- R1 Rethink: Design products with a higher utilisation rate, incorporating multifunctional aspects and contemplating shared models.

- R2 Reduce: Design and manufacture products more efficiently, employing tactics such as reducing material usage, minimising energy consumption, and mitigating pollution. These practices significantly decrease the environmental footprint while enhancing cost-effectiveness and sustainability across the entire value chain.

For example, if a company can access regulatory information through a Digital Product Passport, it might cut its use of virgin plastics for car interiors if the DPP confirms compliance with relevant regulations. This level of supply chain transparency, made available to designers, can also inform and improve the design process for future product versions, leading to more sustainable choices and innovations.

The second set of strategies focuses on extending the lifespan of products, promoting responsible consumption, minimising waste, and conserving resources. Including an exploded parts view or disassembly instructions in a product’s DPP would make it easier to repair, and a log of previous repairs can be kept to see what condition each component is in.

- R3 Reuse: Prolong the lifespan of products and materials by designing them with durability, repairability, and adaptability in mind. Establish systems that facilitate product and component reuse foster a culture of resource conservation and promote sustainable business practices.

- R4 Repair: Enable product functionality through access to repair services, readily available spare parts, and comprehensive repair resources.

- R5 Refurbish: Restore old products and bring them up to date, reducing the demand for new production.

- R6 Remanufacture: Use parts of discarded products to manufacture like-new items with the same function.

- R7 Repurpose: Use discarded products or their parts in a new product with a different function.

Take a drone as another example: its individual components, such as motors and batteries, could each have their own DPP nested within the overarching passport for the drone. This detailed information helps stakeholders determine the optimal timing for maintenance or transition between various R strategies, based on value and sustainability. Essentially, a DPP provides the necessary data to make informed decisions, such as whether it is more beneficial to reuse a motor as is, to refurbish an old motor, or to remanufacture a new one using the existing copper coils while recycling the old magnets.

The final set of strategies relates to the management of materials within products and their useful applications. Here, a DPP can outline compliance mechanisms to show where and how materials can be recycled.

- R8 Recycle: Process products to obtain materials of similar quality, facilitating the recovery of valuable resources and reducing the need for virgin materials.

- R9 Recover: Incinerate materials to recover energy from waste materials that cannot be reused, repaired, refurbished, or recycled, thus generating alternative sources of energy.

For instance, a DPP for a used refrigerator could specify the recycling locations for its metal components, and distinguish between plastics that can be recycled and those that must be composted or incinerated. By providing this detailed breakdown, more parts of the refrigerator can be salvaged and repurposed, reducing the need to resort to less eco-friendly disposal methods like incineration or landfill.

While completely eliminating waste through a closed-loop system may seem like an ambitious target, it is absolutely necessary and possible to reduce waste and maximise resource use today. By collecting and sharing insights into a product’s composition, usage, and recyclability, DPPs can guide efforts to reduce material consumption, facilitate the reuse of components by providing data on product durability, and streamline recycling by identifying which parts can be recovered.

Implementing DPPs for R-strategies can help businesses and societies transition to more sustainable practices, empowering manufacturers and consumers to make informed decisions that align with sustainability principles for a circular economy. Let us embrace the strategies and technologies that will help us create a future where nothing is wasted and everything is valued.